The New Machinery Regulation

The evolution of requirements in the new Machinery Regulation

The requirements of the New Machinery Regulation will have to reflect the technological evolution of the coming decades; for this reason the current requirements will be enriched with new topics that will be crucial for the compliance of products falling under its scope. This article explains the main changes from a technical and conceptual point of view.

Introduction

Recently, the European Commission has supported the agreement reached by the Council of the European Union and the European Parliament on the publication of the new Machinery Regulation (read article on this topic); this will, most likely, lead to the adoption of the new Regulation by spring of the incoming year.

The new Machinery Regulation will have to take into account many points that have already started to emerge in recent years and will characterize industrial technological evolution in the coming decades, below are the three most relevant topics:

a – Introduction of artificial intelligence;

b – Definition of criteria for network security;

c – Implementation of requirements for shared work environments.

Some of these topics are already treated today in both Technical Standards and Regulations as well as in the current Machinery Directive; the new Machinery Regulation will stand as a parallel piece of legislation that will consider only the safety aspects of these issues.

Below we will cover the main innovation aspects of the requirements of the new Machinery Regulation so that you will have a clear idea of how to deal with the new requirements and integrate risk analysis.

The new Annex III

The requirements of the new Machinery Regulation will be listed in Annex III prioritizing the list of products with high hazards (Annex I) and the list of safety components (Annex II); this formal change brings no change from a technical point of view.

The requirements will be structured exactly like those in the current Machinery Directive and will be enriched with new points related to technological developments.

All additions that have been made in reference to the text of the Machinery Directive will be harmonized with the already existing Regulations that also include machines.

Integration of artificial intelligence

The biggest and unprecedented innovation on the text of the current Machinery Directive is certainly the introduction of the topics related to artificial intelligence algorithms. This topic is the most complex and difficult to deal with and will be integrated in a harmonious way to the AI ACT Regulation Requirements of which there is already a proposal within the website of the European Parliament (proposal part 1 and part 2).

The Artificial Intelligence Regulation will deal with this complex topic from different points of view (Security, Ethics, Privacy, Psychological Impact, etc…) and will also include machines if they integrate artificial intelligence algorithms within their embedded software. The requirements of the machine regulation, on the other hand, will deal with artificial intelligence only from the point of view of operator safety.

The purpose of this integration is to ensure that the installed self-learning and self-evolving algorithms do not add new hazards or increase risks throughout the life of the machine.

The first requirement that sees a substantial change is 1.1..6, which concerns ergonomics, and in particular the interface between the operator and the machine. In this sense, the machine both in its initial state and in future evolutions must always ensure safe communication and the possibility of adapting to the operator’s working mode. The manufacturer must ensure that in every current and future condition the principles of cognitive ergonomics and safety in human-machine interaction are respected.

The second very important requirement for this issue is 1.2.1, which concerns the safety and reliability of control systems. The evolution of a machine’s software must in no way lead to a decrease in the level of reliability of control systems with a safety function; if this is true then the evolution of the machine must never exceed certain safety limits determined by the manufacturer. The risk analysis of the machine integrating self-learning and self-evolution algorithms should consider all scenarios and impose limits (e.g., temperature, speed, etc…) that can never be exceeded by the machine. Finally, the command given by the operator must always have the highest priority over any autonomous decision of the machine.

Criteria for network security

Today, almost every machine that goes into operation already has a network connection; this connection allows companies to access production data and in some cases even control and vary machine parameters; a network connection, if not well managed, can allow access and control of the machine to third parties with malicious intent.

This aspect affects one of the cornerstone principles of the Machinery Directive: reasonably foreseeable misuse. Risk analysis must be conducted considering all misuse or accidental situations that may arise during the life stages of the machine. The networking of machines opens a new scenario which would be the intentional misuse with different possible purposes:

a – Blocking production;

b – Damaging production;

c – Data theft;

c – Corruption of security data (terrorist actions).

The only aspect that is relevant to the requirements of the New Machinery Regulations is data corruption, which can lead the machine to behave dangerously and harm the operator; hence the new requirement 1.1.9 – Protection Against Corruption.

The connection of the machine to a network shall in no way lead to a dangerous situation; critical components shall be identified by the manufacturer and properly protected against accidental or intentional damage. A copy of the software log must be maintained with all changes, it must always be possible to check the installed software version easily.

This requirement leads the machine manufacturer to conduct a true risk analysis at the software design stage and requires that all indications concerning verification, maintenance and update of the software are to be specified in the instruction manual. The software’s degree of complexity, which may often include safety features, makes this aspect become critical, as it is with a safety guard or photocell.

Requirement 1.2.1 is also affected by this aspect:

The control system must be designed and built with consideration of the dangers that can arise from external corruptions including “malicious attempts” at tampering; this aspect becomes even more important when we are talking about parts of the machine’s control system that handle safety functions which must not be enabled to be changed from the outside.

Consequently, the manufacturer will have to analyze very carefully the safety aspects of their machine’s connection at the design stage. The software will have to keep in memory, for at least 5 years, the log of the loaded software in order to be able to prove the compliance of the machine with the provisions of the new Machinery Regulation in case this information is requested by the authorities.

Shared work environments

Shared working environments are defined as spaces in which people and machines perform activities at the same time; simultaneous operations both with or without human-machine collaboration can be expected.

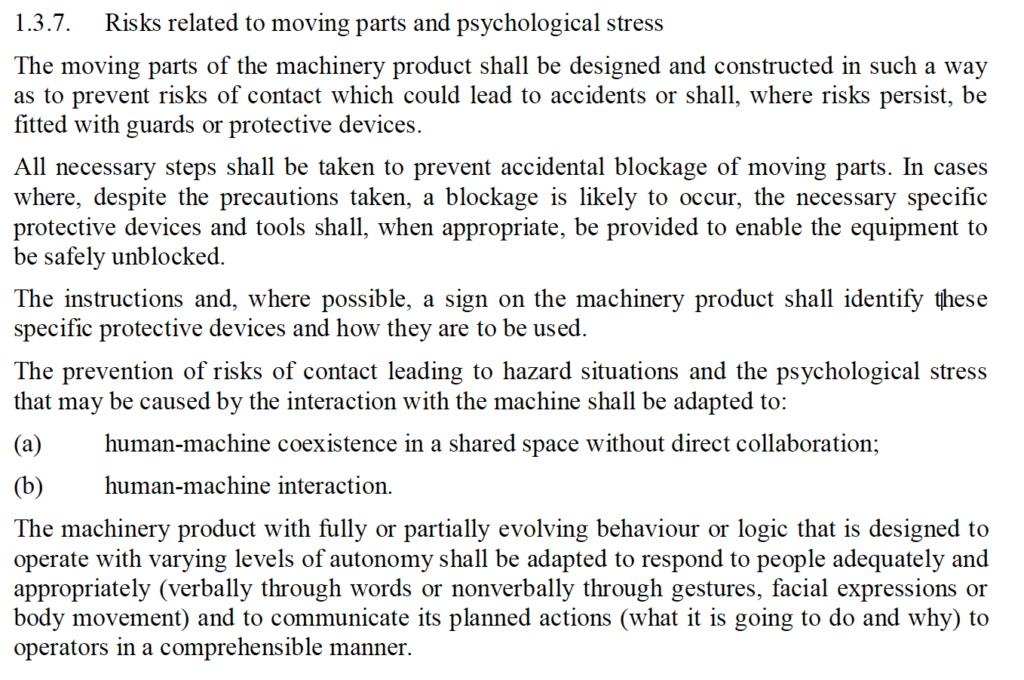

In this case, the new Machinery Regulations take into consideration hazards of physical and psychological nature by substantially modifying requirement 1.3.7:

In a shared environment, no mechanical hazards shall be possible, guards or safety function shall be provided so that the machine is not allowed to harm the operator in any way. Human-machine contact may be provided but only with the condition that it is not dangerous.

Risk analysis must consider, in addition to mechanical hazards, all hazards of a psychological nature that may arise in the shared environment. For this issue, studies are being conducted that show the increased psychological stress load for the operator who has to work together with a machine for many hours a day.

Finally, requirement 1.3.7 states that machines must always be designed considering adaptation to human behavior: the machine must respond to the operator appropriately based on his direct commands, but also on his gestures, words and expressions.

Conclusion

The requirements of the New Machinery Regulation will lead the machinery industry to be increasingly attentive to safety aspects related to new technologies; within the requirements we have seen in this article, a real revolution is in place.

With this in view, the requirements of the regulation pose so many new challenges for both manufacturers and for those of us who are involved in consulting in the area of machine safety. It was certainly a necessary step, one that will take us into the future and enable us to adopt new technologies with an increased sense of awareness and safety.

What can we do for you?

In WAVES ENGINEERING, we deal with machine safety and are keeping up to date with the challenges of the new Regulation.

If you want to stay up-to-date, check your products, or even just want to get to know us, contact us!

WAVES Engineering S.r.l.